conduct a brinell hardness test|brinell hardness test diagram : Big box store The Brinell hardness test is based on the amount of resistance that a solid material offers when it is pressed into by force. Brinell’s method produces a small depression . 26 de set. de 2023 · Seleção Brasileira. Eliminatórias Copa do mundo. Nacionais. Internacionais.

{plog:ftitle_list}

Resultado da 27 de mai. de 2020 · I hope this is only the first page of a 100 pages' book! :D You can do it Godoy sensei! 2020-05-27 16:53:24 is only available to .

The Brinell hardness test is based on the amount of resistance that a solid material offers when it is pressed into by force. Brinell’s method produces a small depression .

In the manufacturing industry, we are measuring the hardness of the metal by various hardness tests and one of them is the Brinell Hardness Test. In this article, we will see its performing methods, advantages, . How to Conduct a Brinell Hardness Test? Conducting a Brinell Hardness Test follows the guidelines in ASTM E10, which specifies its .Brinell hardness testing is a commonly used method for determining the hardness of metals and alloys. The Brinell hardness test formula. When measuring hardness using the Brinell method, .

The Brinell hardness test method as used to determine Brinell hardness, is defined in ASTM E10. Most commonly it is used to test materials that have a structure that is too coarse or that have a surface that is too rough to be tested . EN ISO 6506-1 is a European standard that specifies the requirements for metallic materials' Brinell hardness testing. It outlines the testing method, equipment, calibration, and .Surface preparation. Before the sample material is placed in the Brinell hardness test unit, it must be either: Machined. Ground. Lapped. Polished. Loads. Indentation time: 10-15 seconds. Sample thickness ASTM: At least 10 .Brinell testing of a material with different ball diameters and test forces must be conducted within the same force-diameter index ("Brinell test procedure") in order to enable direct comparison .

The HRB scale typically is used for soft materials such as aluminum and brass alloys. It uses a 1/16-in. ball indenter with a 100-KG test force. Brinell Testing. Brinell testing normally is used for larger, heavy .The Brinell hardness test was originally developed in the late 1800s by the Swedish engineer of the same name. He wanted to find a method to control the quality/hardness of steel. His solution was to press a railway wheel-bearing .Applications for Brinell Methods Brinell testing is suitable for measuring the hardness of rela-tively soft materials, including low-carbon steels, aluminum, lead, copper, and some plastics. The use of a large indenter and high load helps to minimize the effect of surface irregu-larities and yields more accurate hardness values. Soft Materials .

Indentation hardness value is obtained by measuring the depth or the area of the indentation using one of over 12 different test methods. Learn more about hardness testing basics here. The Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method. You should obtain a copy of this standard, read and . The Brinell hardness test is not suitable for very hard materials or hardened surface layers because the ball does not penetrate sufficiently into the material. Higher test loads are not the solution at this point, as this leads to deformation of the carbide ball. The flattening of the ball results in a larger indentation diameter and thus .The Brinell hardness test is a widely used method for assessing the hardness of materials. This chapter will outline the step-by-step procedure for conducting a Brinell hardness test, highlighting the key elements and considerations involved. 1. Preparation of the Specimen. Select a representative specimen that is suitable for Brinell hardness . The Brinell Hardness Test is a straightforward process that is often applied to materials with rough structures, like cast irons or forged metal samples. During the test, a 5mm or 10mm round carbide ball is pressed into the material using a very high test load, usually between 750kg and 3000kg. This action creates an indentation that is .

Brinell Hardness Test. The Brinell hardness test entails measuring the diameter of indentation caused by a constant concentrated force applied by a steel or carbide spherical indenter on a test specimen. The steel ball indenter is first placed in contact with the material before a constant force is applied and maintained for a 10 to 15 second duration, .

Basic principle and practical procedure of the Brinell hardness test - Testing machine - Test piece - Spherical indenter - Basic principle - Definition .The Brinell hardness test method as used to determine Brinell hardness, is defined in ASTM E10. Most commonly it is used to test materials that have a structure that is too coarse or that have a surface that is too rough to be tested using another test method, e.g., castings and forgings. Brinell testing often use a very high test load (3000 . Rockwell hardness testing, Brinell hardness testing, and microhardness testing are all methods used to verify heat treatment results. Capabilities. Processes. Heat Treating. . It’s important to specify which microhardness testing method to conduct as conversions between the values produced by each type of diamond are only approximate.

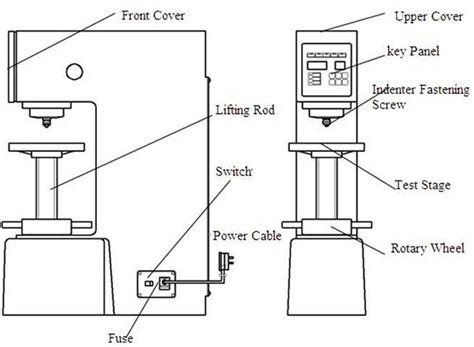

brinell hardness testing machine diagram

IV. How to Conduct a Brinell Hardness Test? Conducting a Brinell Hardness Test follows the guidelines in ASTM E10, which specifies its suitability for coarse-grained or rough-surfaced material that can’t be tested accurately using other techniques. When the Brinell hardness test cannot be used, such as when the material’s HB value is greater than 450 or the sample size is too small, the Rockwell hardness test is used instead. This test involves pressing either a diamond cone with a top angle of 120° or a steel ball with a diameter of 1.59 mm or 3.18 mm into the surface of the tested .

In the Brinell hardness test, an optical method, the size of indentation left by the indenter is measured. In contrast to the likewise optical Vickers method,which involves a pyramid-shaped indenter being pressed into a specimen, the Brinell method uses a spherical indenter.

Description of the Brinell hardness test showing the tester, the microscope for measurement and analysis using a spread sheet. The spreadsheet and SolidWork.Brinell Hardness Test: Using a spherical indenter, this test determines the hardness by measuring the diameter of the indentation created by a known force. It’s suitable for materials with coarse grain structures or rough surfaces. . This method finds utility in scenarios where conducting a static hardness test (typically performed on a . https://engineers.academy/This video outlines how a Brinell hardness test is conducted, as well as explaining how to calculate a value for the Brinell hardne.

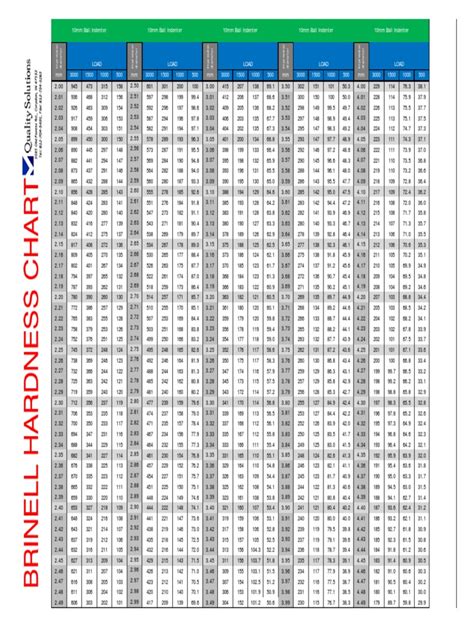

Hardness testing is a vital process in many industries. Our guide explains everything you need to know about this crucial technique. . Selection Table of Brinell Hardness Test P/D 2. Material type: Brinell hardness number/HB: Sample thickness/mm: Relationship between load P and indenter diameter D: Diameter of indenter D/nm: Load P/kgf: Load .This eLearning course focuses on Rockwell and Brinell hardness testing and Vickers and Knoop microhardness testing. Participants will learn about how the tests are performed, test sample requirements, test parameter selection, and testing requirements. The course can be completed in 30 minutes.Brinell Hardness Test. Brinell hardness test is one of the indentation hardness tests developed for hardness testing. In Brinell tests, a hard, spherical indenter is forced under a specific load into the surface of the metal to be tested. The typical test uses a 10 mm (0.39 in) diameter hardened steel ball as an indenter with a 3,000 kgf (29.42 .

The Vickers hardness test is ideal for testing of all metals and is therefore the method with the widest range of application. The hardness test method according to Vickers is described in standards ISO 6507 (Metallic materials – Vickers hardness test – Part 1: Test method) and ASTM E384 (Standard Test Method for Microindentation Hardness (1gf - 200 gf) of Materials . It can conduct tests on a wide range of materials such as: cloth, paper, paint, plywood, leather, tile, glass, rubber etc. It tests the specimen by rotating it while in contact with the grinding wheel and applying the required pressure. . General Information about the Brinell Hardness Test. The Brinell hardness test involves pressing a hard .METHOD FOR BRINELL HARDNESS TEST FOR METALLIC MATERIALS ( Third Revision) 1 Scope This part of ISO 6506 specifies the method for the Brinell hardness test for metallic materials and is applicable up to the limit of 650 HBW. For specific materials and/or products, particular International Standards exist (i.e. ISO 4498-l). 2 Normative referencesBrinell Hardness Scores. . If the biologist set her significance level \(\alpha\) at 0.05 and used the critical value approach to conduct her hypothesis test, she would reject the null hypothesis if her test statistic t* were less than -1.6939 (determined using statistical software or a t .

B. Hardness Test Brinell. Metode Hardness Test Brinell menggunakan indenter berupa bola yang terbuat dari bahan keras, seperti tungsten karbida. Indenter ini ditekan dengan beban tertentu ke permukaan material yang akan diuji. Setelah beban diterapkan selama beberapa waktu, indenter dilepaskan dan bekas penetrasi bola akan terbentuk pada .

brinell hardness testing charts

поточный влагомер удвн

Brinell hardness test is most commonly used to test materials that have a structure that is too rough or too coarse to be tested using other test methods, e.g., castings and forgings. In brinell testing machine the load is applied by a lever mounted on knife edges and carrying a hanger for suspending the required load. The supporting table for .

To conduct a compression test, you must use a standardized test specimen, ASTM E9 (1.0-inch diameter, and 2 inches in height), which is squeezed between the anvils of a compression testing machine. . What are the advantages and disadvantages of the Brinell hardness test? Advantages: It measures the hardness of a relatively large area .

поточный влагомер удвн-1пм

brinell hardness tester diagram

Resultado da 17 de out. de 2023 · Eu achava ser como os vídeos do portal do Zacarias mas me traumatizei eu tenho 12 anos e era para ser tentar não se .

conduct a brinell hardness test|brinell hardness test diagram